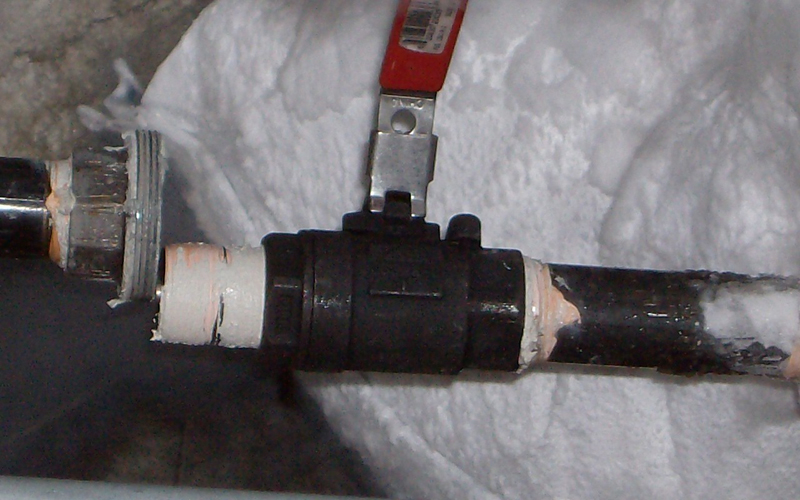

Change leaking valve in a server room.

High pressure (200 psi) / Chilled Water Line with 49% glycol content.

A one inch branch line valve off a three inch main, in the ceiling of a fourth floor server room started leaking and had to be replaced. The line fed the entire building and it was not possible to isolate the valve to allow changing. A building shutdown was also not possible.

N-TWO was called in and the line was frozen allowing the valve to be replaced with very little inconvenience to the building or tenants.

More Photos

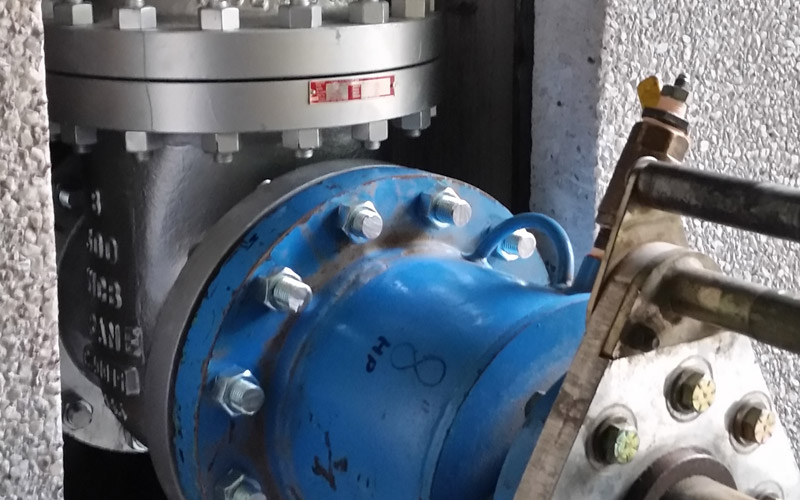

High profile, high security Toronto Datacenter.

2 X 800 Ton Chiller Units.

Building operations consulted with their engineers and decided that the only option was a multiple week solution. A new 1000 ton unit would be installed to maintain service while the existing units were taken offline to be cleaned one at a time. N-TWO was called in to: cut into the existing lines to provide a connection to the new chiller and to install a bypass lines. One 12" pipe freeze was performed along with five hot taps ranging is size from ¾" to 10".

N-TWO was called in and the line was frozen allowing the valve to be replaced with very little inconvenience to the building or tenants.

More Photos

Hot Tapping

Four (4) 14" dia. Hot taps into 18" dia. And 20" dia condenser mains. To tie in new cooling towers.

Once new cooling towers were tied in. Existing cooling towers were removed by freezing the existing 20" dia. Condenser mains 6' upstream from the new cooling tower connections. New cooling towers were operating and the system was not shut down during this process.

More Photos

Hot Tapping

High demand on the chilled water system due to the continuously high temperatures of the summer resulted in the need for supplementary cooling. Three (3) 8" dia. Emergency Hot taps into 16" dia mains. carried out on weekend hours to allow the addition of supplementary cooling via a portable chiller plant. The project was carried requiring no shut down or drainage of the existing chilled water system, allowing the hospital to operate under full capacity.

More Photos

Pipe Freezing

Retrofit of boiler heating system. Two 10" dia. Freezes were carried out to replace two existing butterfly valves that have failed and were allowing water to pass. Freezing allowed this work to take place without draining down the entire system, saving the cost of drain down and fill time as well as chemical treatment of new water.

More Photos

Shrink Fitting

Client attempted to install journal end into roll shaft. Journal end got stuck 1” before bottoming out. N-Two was brought in to move the journal end into its final position. This was achieved by cooling the journal end with liquid nitrogen, causing it to shrink, and heating the roll shaft allowing it to expand. Through the use of both methods the journal end was moved into its final position.

More Photos

Shrink Fitting

Shrinkfit of spindle and spline ends into control arms. 150 control arms completed in one day.

More Photos